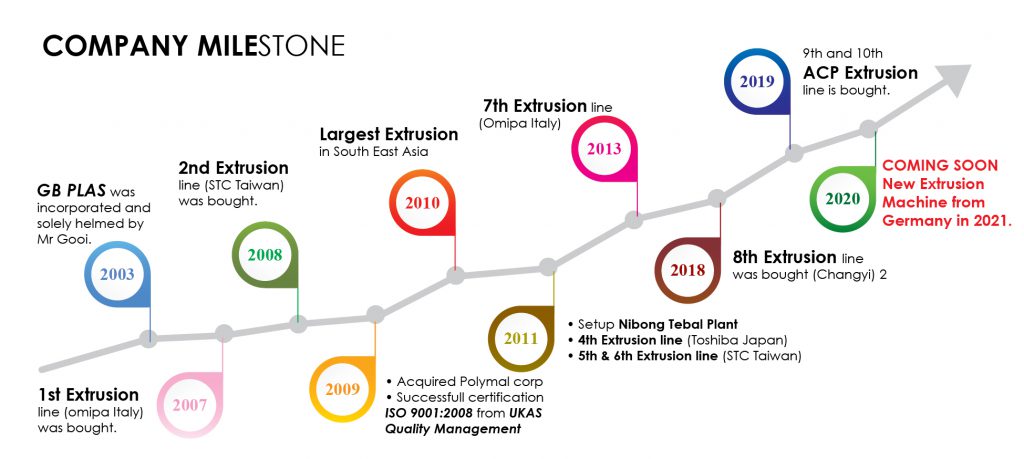

GB PLAS is a global leading plastic specialist with world-class manufacturing capabilities. Our company offers a complete raw material production facility from virgin resin through our state-of-the-art manufacturing process to produce high quality extrusion plastics.

Our manufacturing set-up includes vital key processes such as material purification, material separation and compounding colour, through our re-pelletizer machine.

As a specialist in plastics industry, we able to customize fabricated plastic sheets to any specifications to fulfill customer requirements.

GB Plas uses sophisticated extrusion technology from the Japan and Europe which have the capability of producing different grades of extrusion plastics with different thicknesses to meet customer most exacting demands.

Our manufacturing process employs high-tech machinery imported from the USA and Europe. Their superiority ensures the precision tolerances, consistent color vibrancy and uniform high quality for which we are known. With our advanced technology, we are able to perform a wide range of functions with fast turnabouts to meet the growing needs of the plastic industry.

As soon as they are formed, the plastic sheets are screened for any deformities or defects. Those that do not meet the grade are sent to be scrapped. The plastic sheets that do pass the quality inspection are then wrapped and stored in a spacious warehouse to prevent damage. Each order of plastic sheets is stored separately from each other to facilitate inventory management.

Strict quality control is integrated into every aspect of GB PLAS' operations from the storage of raw materials to production to delivery. Our ISO certified facilities ensure that orders are created to the highest standards with rapid production times.

Copyright ©2020 GB Plas Sdn Bhd (638291-V). All rights reserved.