The Essential Role of Plastic Sheets Today

In today’s fast-paced manufacturing, construction, and design industries, the demand for lightweight, durable, and versatile materials has never been greater. From packaging and signage to roofing and protective barriers, plastic sheets have become the go-to solution for businesses seeking both performance and cost efficiency.

At GB PLAS, we supply high-quality plastic sheets engineered for diverse industrial and commercial applications — helping manufacturers, architects, and designers achieve lasting results with materials built to perform.

What Are Plastic Sheets?

A plastic sheet is a flat, solid material produced from synthetic polymers such as polycarbonate, acrylic, ABS, or polystyrene.

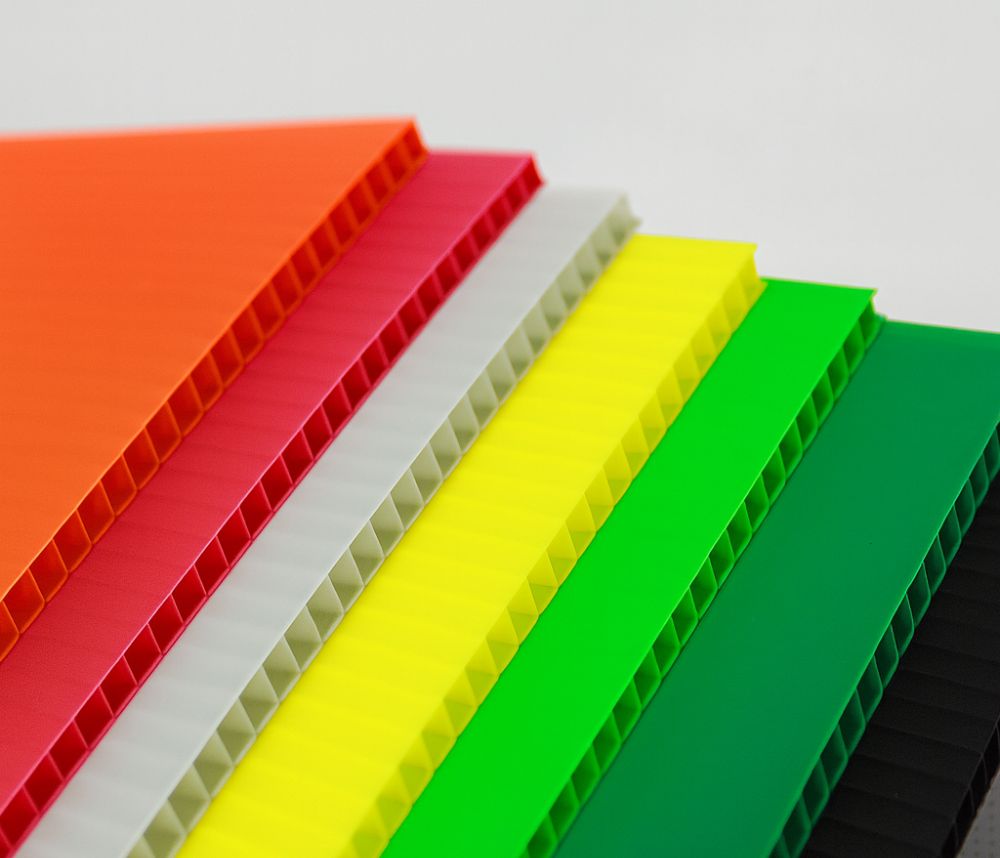

These sheets can be manufactured in a wide variety of thicknesses, colours, and surface finishes, making them adaptable to nearly any environment or function.

Plastic sheets have largely replaced traditional materials like glass, wood, and metal due to their superior combination of strength, flexibility, and affordability.

Popular Types of Plastic Sheets

Choosing the right plastic sheet depends on the project’s performance and aesthetic requirements.

1. Acrylic (PMMA) Sheets

- Known for glass-like clarity and scratch resistance.

- Commonly used for signage, displays, windows, and interior decor.

- Offers UV stability, ensuring long-lasting transparency.

2. Polycarbonate Sheets

- Virtually unbreakable and 250x stronger than glass.

- Ideal for roofing, skylights, machine guards, and protective barriers.

- Provides excellent thermal insulation and UV resistance.

3. ABS Sheets

- Combines strength and flexibility with a textured surface.

- Popular in automotive, electronics, and equipment enclosures.

- Resistant to impact and easy to thermoform into various shapes.

4. Polystyrene Sheets

- Lightweight and cost-effective, suitable for large-scale use.

- Used in construction insulation, packaging, and signage.

- Can be produced with eco-friendly recycled content.

Advantages of Plastic Sheets

Plastic sheets deliver a wide range of benefits that make them indispensable in modern industries:

Durability

Resistant to corrosion, impact, and weather, plastic sheets offer long-lasting performance in both indoor and outdoor environments.

Lightweight

Compared to materials like metal or glass, plastics are easier to transport, install, and handle, reducing labour and structural costs.

Design Flexibility

Available in clear, opaque, frosted, coloured, or textured finishes, plastic sheets can match any design or functional need.

Thermal and Acoustic Insulation

Certain plastics — such as twin-wall polycarbonate — provide excellent insulation, improving energy efficiency and comfort.

Low Maintenance

Plastic surfaces are easy to clean and require minimal upkeep, saving long-term operational costs.

Sustainability

Modern plastic sheets can include recycled content and be fully recyclable, supporting greener production practices.

Applications Across Industries

Plastic sheets are one of the most adaptable materials across global markets. Common applications include:

- Construction: Wall cladding, roofing, skylights, and partitions.

- Advertising: Signboards, display panels, and lightboxes.

- Automotive: Trims, dashboards, protective panels.

- Industrial: Machine guards, packaging, and storage bins.

- Retail & Interior Design: Furniture, shelves, displays, and fixtures.

- Agriculture: Greenhouses, shades, and protective barriers.

Plastic Sheets vs Traditional Materials

Feature | Plastic Sheets | Glass | Metal | Wood |

|---|---|---|---|---|

Weight |

Lightweight |

Heavy |

Medium |

Medium |

Durability |

High |

Fragile |

Prone to rust |

Prone to rot |

Cost |

Affordable |

Expensive |

Medium |

Medium |

Maintenance |

Low |

High |

Medium |

High |

Workability |

Easy to cut/form |

Difficult |

Limited |

Easy |

UV/Weather Resistance |

Excellent (UV-coated) |

Poor |

Varies |

Poor |

Verdict: Plastic sheets outperform traditional materials in versatility, safety, and total cost of ownership — making them the preferred option for both large-scale industries and creative applications.

Why Choose GB PLAS for Plastic Sheets

As one of Malaysia’s leading plastic sheet manufacturers and suppliers, GB PLAS stands for innovation, precision, and quality.

- 18+ Years of Expertise – Proven track record in extrusion and thermoplastic manufacturing.

- ISO-Certified Quality – Ensuring reliable performance and consistency in every sheet.

- Wide Product Range – From acrylic and polycarbonate to ABS and polystyrene.

- Advanced Technology – Machinery from Japan, Europe, and the USA for top-tier results.

- Eco-Friendly Commitment – Sustainable production with recyclable materials.

- Global Reach – Trusted by clients in over 60 countries worldwide.

Conclusion: Plastic Sheets that Power Innovation

From construction and automotive manufacturing to creative design and signage, plastic sheets are reshaping industries with their balance of durability, cost-efficiency, and versatility.

At GB PLAS, we provide high-quality, customizable plastic sheets designed to meet your project’s technical and visual needs — built to last and perform.

Contact us today for expert guidance and a free quotation on the best plastic sheet solutions for your business.

Plastic Sheet Products

GB PLAS specializes in delivering high-quality, customized plastic sheet solutions for a wide range of industries, including roofing, advertising, automation, automotive, building, furniture, and more.

Read More ...