Plastic Sheets for Construction & Signage: What Malaysian Buyers Should Know

Plastic sheets are everywhere in Malaysia’s construction and signage industry — from factory roofs and shop awnings to signboards, partitions, and interior panels.

But not all plastic sheets are the same. Choosing the wrong type can lead to yellowing, cracking, heat buildup, or even safety issues.

If you’re a contractor, designer, business owner, or procurement team, this guide will help you understand which plastic sheets work best for Malaysian weather, applications, and budgets.

Why Plastic Sheets Are Widely Used in Malaysia

Malaysia’s hot, humid climate and frequent rain make material selection critical. Plastic sheets are popular because they:

- Are lighter than glass

- Offer good impact resistance

- Are easier and faster to install

- Come in UV-protected and heat-resistant options

- Are generally more cost-effective

That said, performance depends heavily on material type, thickness, and quality.

Common Types of Plastic Sheets Used in Construction & Signage

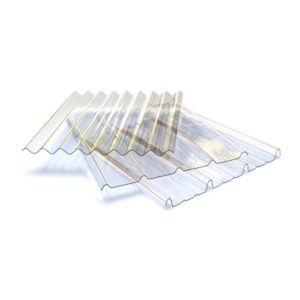

1. Polycarbonate Sheets

One of the most widely used plastic sheets in Malaysia.

Best for:

Roofing

Skylights

Awnings

Walkways

Canopies

Why buyers choose it:

Extremely impact-resistant (much stronger than acrylic)

UV-coated options available

Handles heat and heavy rain well

Things to note:

Hollow polycarbonate is lighter and cheaper

Solid polycarbonate is stronger but more expensive

Polycarbonate Sheets

Read More ...

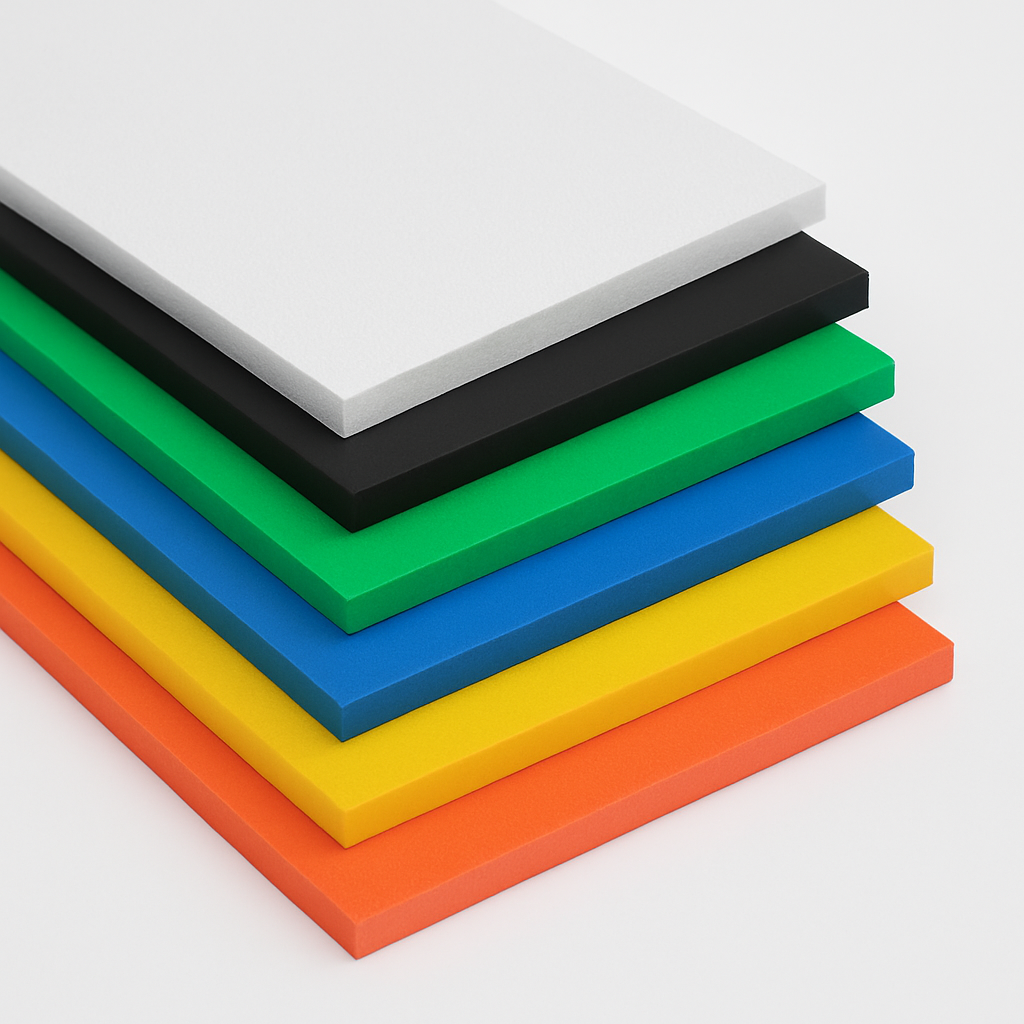

2. Acrylic Sheets

Often used when clarity and appearance matter.

Best for:

Signage

Lightboxes

Display panels

Interior decorative panels

Why buyers choose it:

Glass-like clarity

Clean, professional look

Easy to cut and fabricate

Limitations:

Less impact-resistant than polycarbonate

Not ideal for high-impact outdoor roofing

Acrylic Sheets

Read More ...

3. Polystyrene Board

A lightweight option mainly for indoor or temporary use.

Best for:

Insulation

Partition backing

Packaging

Temporary displays

Why buyers choose it:

Lightweight

Easy to handle

Cost-effective

Limitations:

Lower strength

Not suitable for outdoor exposure without protection

Polystyrene Board

Read More ...

4. Aluminium Composite Panel (ACP)

Technically not a “plastic sheet” alone, but widely grouped in the same category.

Best for:

Facades

Signboards

Cladding

Awnings

Why buyers choose it:

Strong and durable

Clean, modern appearance

Weather-resistant

Aluminium Composite Panel (ACP)

Read More ...

Key Factors Malaysian Buyers Must Consider

1. Weather Resistance

Malaysia’s UV exposure and rainfall are no joke.

Always check for:

UV coating (especially for roofing)

Heat resistance

Warranty period

Cheap, non-UV plastic sheets may turn yellow or brittle within a year.

2. Thickness Matters

Thickness affects durability, noise, and lifespan.

General guidance:

Roofing & awnings: thicker sheets perform better

Signage & displays: thinner sheets may be sufficient

High-impact areas: always go thicker

3. Indoor vs Outdoor Use

Not every plastic sheet is meant for outdoor use.

Outdoor: polycarbonate, ACP

Indoor: acrylic, polystyrene board

Using indoor-grade sheets outdoors is a common (and costly) mistake.

4. Application-Specific Needs

Ask yourself:

Is this for roofing, signage, partition, or display?

Does it need light transmission?

Does it need to withstand impact or heat?

A signage panel and a factory roof require very different materials.

Common Mistakes Buyers Make

Choosing based on price only

Ignoring UV protection

Using acrylic where polycarbonate is required

Not checking sheet thickness

Buying from suppliers with inconsistent quality

These mistakes often lead to replacement costs that exceed initial savings.

How to Choose the Right Plastic Supplier in Malaysia

A reliable plastic supplier should:

Offer multiple material options

Explain pros & cons clearly

Stock consistent thickness and quality

Understand local construction needs

Provide after-sales advice

Material knowledge is just as important as product availability.

Summary

Plastic sheets are a smart choice for construction and signage in Malaysia — if you choose the right type for the right job.

Understanding material differences, weather suitability, and application requirements can save you time, money, and headaches down the line.

When in doubt, always consult a supplier who understands both materials and Malaysian conditions, not just pricing.

Plastic Sheet Products

GB PLAS delivers high-quality plastic sheet solutions for roofing, advertising, automotive, and more—crafted with precision and eco-friendly technology...