Choosing the Right Material Matters

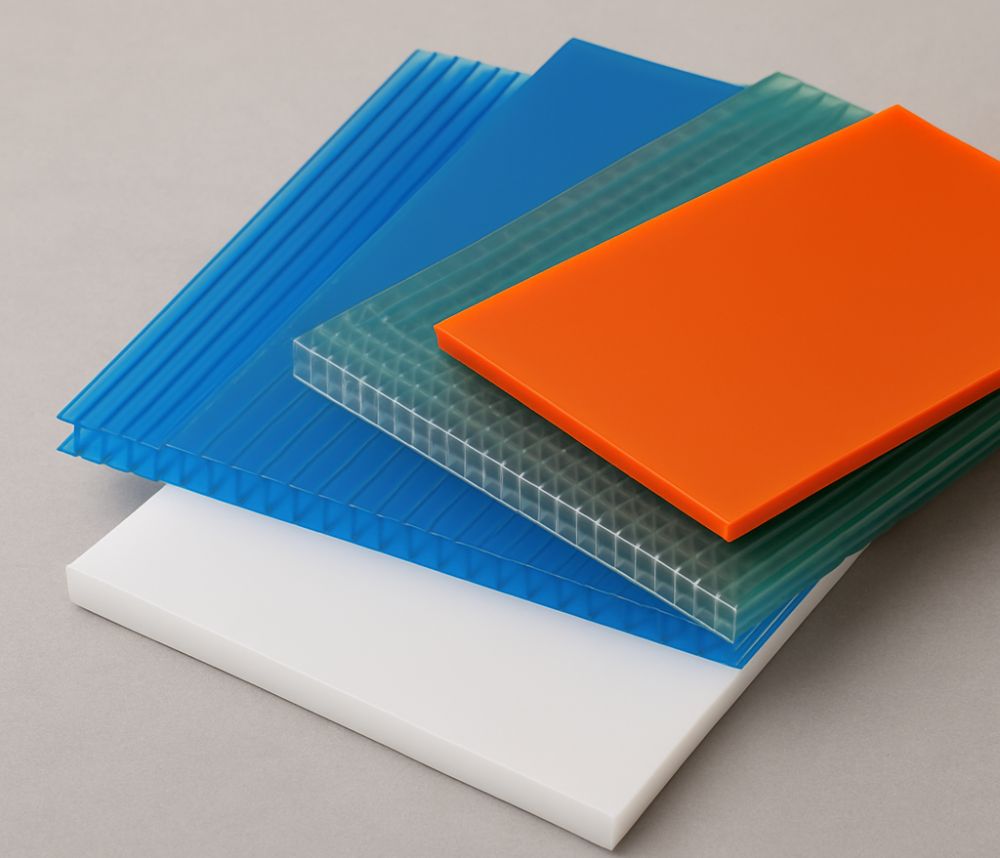

Whether you’re working on a construction project, signage, or interior design, selecting the right material is critical. With so many options available, buyers often ask: What’s the difference between plastic sheets, acrylic sheets, and polycarbonate sheets?

Each material has unique strengths and weaknesses. In this guide, we’ll break down their properties, uses, durability, and cost factors so you can make the best choice for your project.

Understanding the Basics

- Plastic Sheets

A general term that covers a wide range of polymer-based sheets, including acrylic, polycarbonate, ABS, and polystyrene. Plastic sheets are valued for their versatility, lightweight design, and cost-effectiveness.

- Acrylic Sheets

Acrylic, also known as PMMA (polymethyl methacrylate), is a transparent thermoplastic often used as a substitute for glass. It offers high clarity, scratch resistance, and UV stability. - Polycarbonate Sheets

Polycarbonate is a tough, transparent plastic known for being virtually unbreakable. It is 250 times stronger than glass yet lightweight, making it the preferred choice for roofing, safety barriers, and industrial applications.

Key Differences at a Glance

Feature | Plastic Sheets (General) | Acrylic Sheets | Polycarbonate Sheets |

|---|---|---|---|

Strength |

Moderate |

Good |

Excellent (virtually unbreakable) |

Weight |

Lightweight |

Lightweight |

Lightweight |

Clarity |

Varies by type |

Crystal Clear |

High (slightly less than acrylic) |

UV Resistance |

Depends on material |

Excellent |

Excellent with UV coating |

Cost |

Most affordable |

Moderate |

Higher upfront, but long-term savings |

Applications |

Packaging, signage, general use |

Displays, signage, windows |

Roofing, safety barriers, industrial panels |

When to Choose Each Material

Choose Plastic Sheets if:

You need a budget-friendly solution.

The project involves general-purpose use like packaging, protective covers, or temporary structures.

Customization in thickness, color, or texture is more important than strength.

Choose Acrylic Sheets if:

You want maximum clarity similar to glass.

The project involves signage, displays, or decorative panels.

Scratch resistance and UV stability are a priority.

Choose Polycarbonate Sheets if:

You need maximum impact resistance (safety and durability).

The project involves roofing, skylights, machine guards, or outdoor barriers.

- You want long-term reliability even in extreme weather conditions.

Cost Comparison

- Plastic Sheets (General): Lowest cost, best for large-scale projects where price matters most.

- Acrylic Sheets: Mid-range price, ideal for projects that balance aesthetics and durability.

- Polycarbonate Sheets: Higher initial investment, but reduced maintenance and replacement costs make it more cost-effective in the long run.

Final Thoughts: Which One Should You Choose?

When it comes to plastic sheet vs acrylic vs polycarbonate, there’s no one-size-fits-all answer.

- If you’re on a budget and need versatility, choose plastic sheets.

- If you want aesthetic appeal and clarity, go with acrylic sheets.

- If you need strength and durability, especially for roofing or industrial use, polycarbonate sheets are the best investment.

At GB PLAS, we help clients choose the right material based on function, budget, and long-term goals.

Plastic Sheet Products

GB PLAS specializes in delivering high-quality, customized plastic sheet solutions for a wide range of industries, including roofing, advertising, automation, automotive, building, furniture, and more.

Read More ...